日本品質でアクセサリに輝きと安心を

Amplify inner confidence and joy by adorning it. Accessories possess the power to let people's inner glow shine through beyond outward beauty. SakuLux®, a leading brand of accessory wires, is dedicated to enriching users' lives with long-lasting beauty and brilliance. At SakuLux®, we strive to achieve this by manufacturing high-quality wires in our own domestic factories. We use advanced technology and rigorous quality control. We ensure our products embody the spirit of Japanese craftsmanship. We're grateful that users around the world appreciate our commitment to quality. We at SakuLux® are committed to illuminating the lives of people around the world, both now and in the future.

日本品質でアクセサリに輝きと安心を

Amplify inner confidence and joy by adorning it. Accessories possess the power to let people's inner glow shine through beyond outward beauty. SakuLux®, a leading brand of accessory wires, is dedicated to enriching users' lives with long-lasting beauty and brilliance. At SakuLux®, we strive to achieve this by manufacturing high-quality wires in our own domestic factories. We use advanced technology and rigorous quality control. We ensure our products embody the spirit of Japanese craftsmanship. We're grateful that users around the world appreciate our commitment to quality. We at SakuLux® are committed to illuminating the lives of people around the world, both now and in the future.

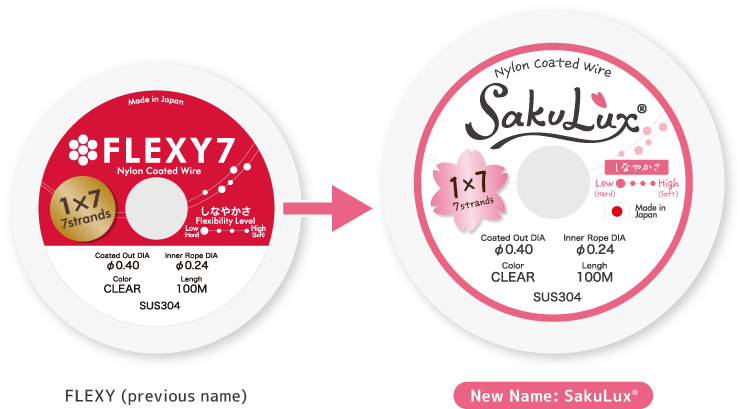

Introducing SakuLux®,

the new brand formerly known as FLEXY.

Accessory use stainless steel rope product FLEXY is rebranded to SakuLux® from January 2024.

Rebrand and Trademark Registration

SakuLux® has obtained the trademark and design rights in both Japan and China.

Since about 10 years ago when we started the brand FLEXY,

we have been providing our products without registering a trademark.

However, in recent years, it has come to our attention that the FLEXY trademark has been registered in China without our knowledge or consent.

This has led to the unauthorized distribution of low-quality wires under the FLEXY name, using packaging identical to ours.

We recognized that this situation could lead to confusion and misuse among our valued customers.

It also posed a significant threat to our brand.

Therefore, we made the decision to retain our existing products while rebranding under the new name SakuLux®.

We have also obtained the trademark and design right of SakuLux®.

With our new brand name, we remain committed to providing the same high-quality accessory use wires as before.

Brand Concept

Sakura x Luxury

The inspiration behind our new brand name comes from “Sakura”,

the symbol of Japan, and the word “Luxury”.

he new brand name embodies two cherished values:

“Sakura” evokes the graceful elegance of accessories that enhance one's personal style.

“Luxury” reflects our pride in offering high-quality wires, made with Japanese precision.

Voice of Inventors

Our wires are made from the selection of raw materials, to the final manufacturing process.

We assure the stable strength and the resistance to natural curving of our wires.

This effort gave us absolute confidence towards the high quality.

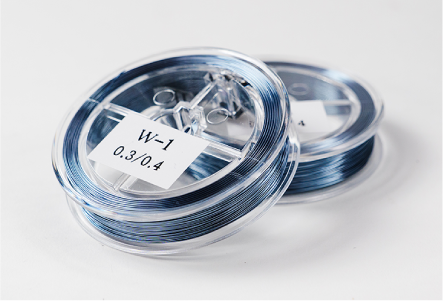

We are able to provide different color options that fit the needs.

And also, the package is meticulously designed with the delicate beauty of the Sakura flower in mind.

Award-winning Quality

SakuLux®, a brand renowned for its unwavering dedication to Made-in-Japan quality, has garnered numerous awards and certifications for its exceptional manufacturing techniques and unwavering commitment to excellence..

Osaka Manufacturing Excellent Company Award

The “TAKUMI” (匠) is a prestigious recognition program that honors small and medium-sized manufacturing enterprises in Osaka Prefecture for their exceptional overall capabilities. We have proudly received the “TAKUMI” (匠) Award in 2009.

Top-notch skills and strict quality control

deliver the best accessory wire.

4 Product Lineups

We provide 4 wire product lineups, which have different twisting combinations.

You can select the one which fits the need according to the usage and product features.

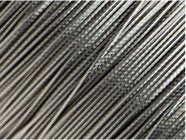

SakuLux® 1×7 (7 strands)

7 strands of stainless steel wire is the standard structure of stranded wire and a basic product for accessories. 7strands has strength and flexibility, and fits simple designs such as a string of beads.

About the structure

7 strands type is twisted with 7 wires which is 1 core wire surrounded with 6 wires. This is the most basic structure and strictly represents the high-level skill of the crafting process.

Stainless

| Nylon Coated Out DIA (Inner Rope DIA) (mm) | Weight (Coated) (g/1000m) |

|---|---|

| 0.20 (0.15 – #47×7) | 160 |

| 0.25 (0.18 – #46×7) | 250 |

| 0.30 (0.18 – #46×7) | 260 |

| 0.35 (0.21 – #45×7) | 320 |

| 0.40 (0.24 – #44×7) | 410 |

| 0.45 (0.27 – #43×7) | 490 |

| 0.50 (0.30 – #42×7) | 610 |

| 0.60 (0.36 – #40×7) | 870 |

| 0.70 (0.45 – #38×7) | 1350 |

Silver Plated and Gold Plated

| Nylon Coated Out DIA (Inner Rope DIA) (mm) | Weight (Coated) (g/1000m) |

|---|---|

| 0.40 (0.30 – #42 x 7) | 580 |

Colors

-

-

CLEAR? CLEAR: It is a versatile color that is easy to combine with other colors and materials, making it suitable for a wide range of users from beginners to experts.

-

-

BLACK? BLACK: Classic and bold, black is a timeless color that adds a cool, commanding presence to any style.

-

-

WHITE? WHITE: It symbolizes purity and elegance, and is a versatile color that complements any style with its clean and fresh appearance.

-

-

PEARL SILVER? PEARL SILVER: The refined pearl color adds a subtle elegance with its soft luster, making it a versatile choice that is both classic and modern, suitable for a wide range of occasions.

-

-

METALIC GOLD? METALIC GOLD: Gold, with its radiant and luxurious luster, imparts a sense of opulence and elevates any special accessory.

-

- BRONZE

-

- COPPER

-

- MONTANA

-

- GREEN

-

- RED

-

- PINK

-

- TINT GREEN

-

- LIGHT BORWN

-

- PINK GOLD

SakuLux® 1×19 (19 strands)

The 19 strands type is positioned in between 7 strands (1x7) type which has strength, and 49 strands (7x7) type which has flexibility, and is closer to the strength side. With the balanced strength and flexibility, it has a certain resistance to breakage.

About the structure

The 19 strands type features a construction with 19 strands, which is composed and twisted from a central core wire surrounded by 6 wires, and wrapped in a further layer of 12 wires. This is resulting in a circular cross-section and offers high strength while maintaining flexibility. It is also used in industrial purposes where strengths are needed.

Stainless

| Nylon Coated Out DIA (Inner Rope DIA) (mm) | Weight (Coated) (g/1000m) |

|---|---|

| 0.30 (0.20) | 250 |

| 0.35 (0.25) | 370 |

| 0.40 (0.30) | 520 |

| 0.45 (0.35) | 680 |

| 0.60 (0.45) | 1090 |

Silver Plated and Gold Plated

| Nylon Coated Out DIA (Inner Rope DIA) (mm) | Weight (Coated) (g/1000m) |

|---|---|

| 0.35 (0.25) | 370 |

| 0.45 (0.35) | 680 |

| 0.60 (0.45) | 1090 |

Colors

-

-

CLEAR? CLEAR: It is a versatile color that is easy to combine with other colors and materials, making it suitable for a wide range of users from beginners to experts.

-

- Others

(made to order)

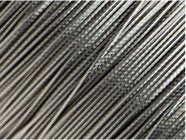

SakuLux® 3×7 (21 strands)

The 21 strands type is positioned in between 7 strands (1x7) type which has strength and 49 strands (7x7) type which has flexibility, and is closer to the flexibility side. With the high flexibility and moderate strength, it offers a certain fluid bendy.

About the structure

The 21 strands type is twisted from 3 sets of 7 strands type wire, each set is composed of a central core wire surrounded by 6 wires. It has a triangular cross-section, which offers high flexibility while maintaining strength.

Stainless

| Nylon Coated Out DIA (Inner Rope DIA) (mm) | Weight (Coated) (g/1000m) |

|---|---|

| 0.30 (0.19) | 250 |

| 0.35 (0.25) | 370 |

| 0.45 (0.38) | 680 |

| 0.50 (0.38) | 690 |

| 0.60 (0.44) | 1090 |

Colors

-

-

CLEAR? CLEAR: It is a versatile color that is easy to combine with other colors and materials, making it suitable for a wide range of users from beginners to experts.

-

- Others

(made to order)

SakuLux® 7×7 (49 strands)

The 49 strands type has the highest flexibility within the lineups. Its silk-like flexibility is high and able to offer V-shape necklines. It also has moderate strength, therefore complicated and delicate creations can be made.

About the structure

The strand wires used in the 49 strands type, are thinner than ones used in 7 strands type, giving high flexibility and ability for complicated designs. A structure that explains our techniques allowing us to craft thinner and stronger stand wires.

Stainless

| Nylon Coated Out DIA (Inner Rope DIA) (mm) | Weight (Coated) (g/1000m) |

|---|---|

| 0.25 (0.18) | 210 |

| 0.30 (0.22) | 236 |

| 0.36 (0.27) | 400 |

| 0.45 (0.36) | 650 |

| 0.60 (0.45) | 1030 |

Silver Plated and Gold Plated

| Nylon Coated Out DIA (Inner Rope DIA) (mm) | Weight (Coated) (g/1000m) |

|---|---|

| 0.36 (0.27) | 400 |

| 0.45 (0.36) | 650 |

| 0.60 (0.45) | 1030 |

Colors

-

-

CLEAR? CLEAR: It is a versatile color that is easy to combine with other colors and materials, making it suitable for a wide range of users from beginners to experts.

-

-

BLACK? BLACK: Classic and bold, black is a timeless color that adds a cool, commanding presence to any style.

-

-

WHITE? WHITE: It symbolizes purity and elegance, and is a versatile color that complements any style with its clean and fresh appearance.

-

-

PEARL SILVER? PEARL SILVER: The refined pearl color adds a subtle elegance with its soft luster, making it a versatile choice that is both classic and modern, suitable for a wide range of occasions.

-

-

METALIC GOLD? METALIC GOLD: Gold, with its radiant and luxurious luster, imparts a sense of opulence and elevates any special accessory.

-

- BRONZE

-

- COPPER

-

- MONTANA

-

- GREEN

-

- RED

-

- PINK

-

- TINT GREEN

-

- LIGHT BORWN

-

- PINK GOLD

Comparison of SakuLux® and Counterfeits

Stable Product Quality

By comparing to counterfeits, SakuLux® wires have stable quality that have almost no inconsistencies of strengths or wire diameters. This achieves a consistently reliable user experience.

Standardized Length

All wire products we provide undergo rigorous quality and length inspections by our experienced professionals, ensuring minimal inconsistencies of wire length.

Minimal Kinks (Low coiling)

Most of those counterfeits overseas are made by metal strings with low degree of resilience, resulting in kinks or coils remaining after being pulled from the spools.

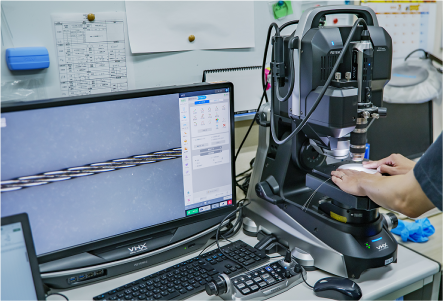

Rigorous Product Quality Controls

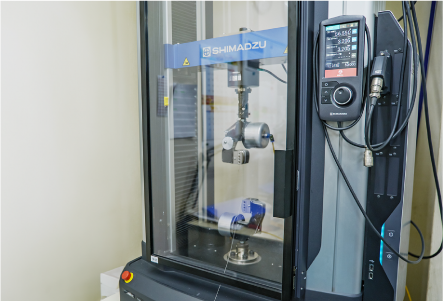

Rigorous Inspections by Instrumentations

Tensile testing machines and outer-diameter measuring machines are equipped. We have standardized procedures to test wires’ strengths and wire diameters rigorously.

Professional Inspectors and Tests

To maintain our high product quality, our professionals inspectors operate 10 quality tests (7 standard wire twisting tests, strength, DIA, hand touch).

In-House Integrated Production

We operate our own in-house factory in Japan, where we handle the entire production process, from procuring raw materials, wire twisting, wire coating, to completing the final products.

Production Process

We maintain rigorous quality control throughout the entire production process in our own in-house factory, performing the entire production process from wire extension of stainless raw material, to packaging and shipping. Additionally, new product developments can be committed to meet the needs of our customers.

Wire Extension

Thick wire materials are being processed phase by phase by usage of diamond dies. Wire diameters ranging from 2 μm (0.009 mm) to 0.20 mm can be processed.

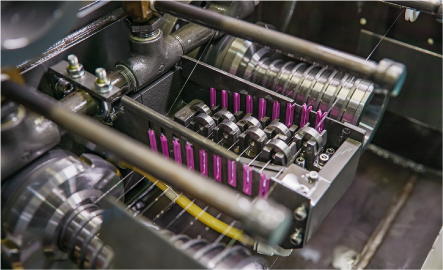

Wire Twisting

The processed wires in the above phase, are being twisted in different combinations. Starting from the basic 7 strands twisting (1x7), variations of standard can be processed.

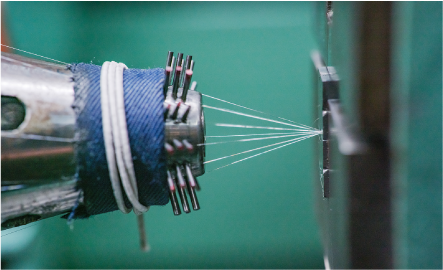

Wire Coating

Wires are coated with polyamide resins (nylon 6, nylon 12, etc.) using extrusion. Coating with a thickness of 0.03 mm to 0.30 mm is possible and color coating is also available upon request.

Product Quality Inspection

Experienced professionals perform tests like tensile testing, outer diameter measurement, eccentricity measurement.

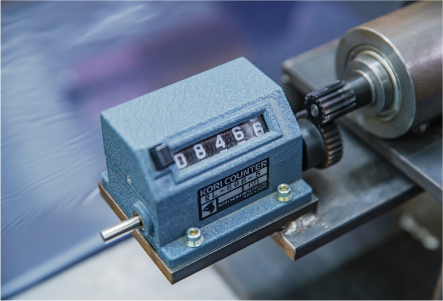

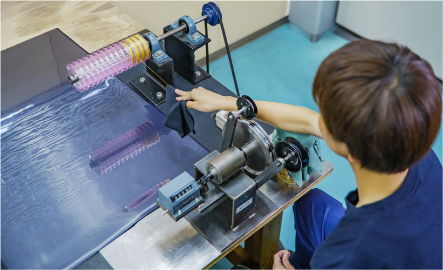

Wire rewinding

The finished final products are inspected by hand and eye by the inspector while measuring the length, and are rewound to an arbitrary length.

FAQ

We sum up the following questions that are asked frequently. Please check here first if you have any questions.

If you have any problems that cannot be resolved here, please contact us by this email address.

Another specific length is available if needed.

< Only Japanese information is available. >

一般的にステンレスは食器類や家庭用具、更には医療器具にも使われている事から安全性の高い金属と言われており、日常的な使用方法であれば人体に影響はございません。

※通常環境下以外での人体への影響につきまして、弊社では責任を負いかねますので使用はお控え下さい。

ナイロン(ポリアミド)は多くの日用品やスポーツ用品にも使われている事から安全性の高い素材と言われており、日常的な使用方法であれば人体に影響はございません。

※通常環境下以外での人体への影響につきまして、弊社では責任を負いかねますので使用はお控え下さい。

SakuLux®‘s nylon coating is highly tenacious and thus removing it without damaging the wire itself is difficult. There is a possibility to remove it however no guidelines are available and we cannot be held responsible for circumstances resulted

Please contact the store where you purchased the product.